By clicking on one of these buttons you can pass on directly to the section of the site that interests you most:

| Actually, what is an organ and where does the name come from?

The term "organ" comes from the Greek "organon" (organon) which basically means "tool" or "instrument". From this the Latin term "organum" was derived. So if a Greek or Latin text is talking about an "organ" it doesn't necessarily mean an organ in our sense. It was only in the late Middle Ages that the term "organ" was reduced to the pipe organ we would think of. In 1919 Curt Sachs defined the organ as follows: "The organ is an aerophone (modifier of air sounds) consisting of single tone pipes arranged in a scale worked by a blower and switched on by keys on a keyboard." This means there are three main elements in an organ, the pipes, the blower(s) and the keyboard(s). |

| Structure on an organ with several manuals

The first organs had only one manual with few keys and accordingly only few pipes. In the late Middle Ages the church organ developed into its present form in Europe - particularly in Germany, Belgium and The Netherlands -, the "Great" organ (or "Hauptwerk") being fixed to the wall and another Rückpositiv (Positive / Choir) organ sitting between the player's back and the balustrade of the gallery. Thus the organ consisted of two divisions each of which was worked by its own keyboard (manual). Then also a keyboard worked by the feet (pedal) was added. As early as in the 16th century even more divisions were added to the organ, e.g. a "Brustwerk" (chest division) or an "Oberwerk" (upper division at the top of the "Great"), each having its own manual. So large organs had three to four manuals, the largest organs today have up to seven manuals. |

|

|

Each division had several stops (voices), i.e. sets of pipes of different construction that could produce different timbres.

The way these rows of pipes (ranks, stops) are arranged is called stoplist (disposition).

The different divisions were arranged in a way that each division had its own sound, the Great as the backbone of the organ was to have a majestic sound, the Positive in most cases

had a clearer sound and included some additional solo voices, the pedal division had the bass voices. This so-called Werkprinzip (principle of relationship between divisions) is still applied in most organs today as you can see for instance in the organ of the Erfurt Cathedral (left):

|

|

Romantic organs aimed at imitating a large orchestra, so a series of new pipe shapes with names indicating other musical instruments were introduced. By disposing many stops in the pitch

of the original instruments (8' or equal pitch, for an explanation click here) the sound of these Romantic organs leant much more towards

the level tone as opposed to the sharp sound of baroque organs rich in overtones and dominated by mixtures. Today's organs try to combine both periods and sound ideals, i.e. they add Romantic stops or, in large organs, even entire Romantic divisions (preferably the Swell) to a baroque basis constructed according to the "Werkprinzip". This way works of all musical periods can be interpreted on one organ. The diagram on the right shows a typical two-manualled organ with Great and Positive. You can see the mechanical tracker action with roller boards connecting the keys of the manuals to the valves of the wind chests (for an explanation click here) on which the pipes are arranged in rows. Looking at the different shapes of the pipes you can tell the stoplist of the Great and the Positive. From left (in the back of the organ) to right (up front in the facade) there are in the Great:Click here for further explanations of pipe lengths and pitches, click here for descriptions and sound samples of the different types of pipes and stops. The visible parts, i.e. the rows of pipes in the front are called the facade. Most pipes, though, are hidden behind as you can see in the cross section. In most cases the so-called Principals (those well-known cylindrical polished tin pipes) are positioned in the facade while the ones deemed less attractive due to the way they are constructed are sitting in the back rows. In some, especially larger, organs you will find some pipes arranged horizontally in the facade, they are called Spanish Trumpets. They owe their name to the fact that as early as in the 16th century trumpet stops in Spain and Portugal were arranged horizontically in the facade. Due to their conical resonator they do not only look very impressive, their volume dominates the sound of the whole organ as well. |

|

|

|

|

|

The Granada Cathedral organ, a Classical Spanish organ (dating from the 18th century) with the characteristic Spanish horizontal trumpets. Organs in Spain at that period used to be double instruments with double facades: the organs faced each other and each had one side of the facade facing towards the nave (cf. pictures) and one to the side aisle. Both organs can be played separately via their own consoles (for an explanation click here). |

Spanish trumpets (Tuba 16', 8' and 4') of the Ulm Cathedral with the Principal 16' of the Great. Just this one division of this huge organ is bigger than most other organs are in their entirety. |

||

Now this is what organs look like behind the facade, if you take a look at their pipe chambers: |

||

|

|

|

Pipes of the legendary "Vox humana" of the Weingarten Basilica organ. They belong to the family of reeds (for an explanation click here). The characteristic shape of their resonator makes for their typical sound. |

View of the pipe chamber of the Wiesbaden Marktkirche (Market Church) Great division. Note the different rows of pipes (stops / ranks) that get smaller and smaller as their pitch goes up and the different shapes and materials (metal, wood). Next to the wind chest on the bottom that all the pipes are sitting on you will notice the motors for the electric stop action that can turn the different sets of pipes on and off (for more information click here). |

|

| The Console

The console is the control center of the whole instrument. It contains the keyboards (manuals and the pedalboard). Drawknobs are arranged to the left and right of the manuals. They serve to pick the rows of pipes / stops (and consequently timbres) that are going to be used. In historic organs they are connected to a mechanical action, most modern organs have electric switches instead. The advantage of electric action is that you can save a combination of stops and later on recall it by just pushing a button (for an explanation click here). Finally the console includes some special aids for playing, such as couplers, swell pedals, etc. (for more information click here). |

||

|

|

|

Console of the Brandenburg Cathedral organ (1725) with drawknobs on the left and right. Note a peculiarity that many organ consoles have, the reverse coloring of the keys on the manuals, as opposed to piano keys whole tones are black, half tones white. |

Weingarten Basilica (1750). The console is detached so that the organist is facing the congregation. This was a novelty then and a technical masterpiece as all 6,631 pipes had to be connected with the keys via mechanical action over a distance of up to 20 m (67 ft) and even around some corners. |

Main Console of the Passau Cathedral organ (1981), the largest organ in Europe (fifth largest in the world) with 5 manuals, 327 ranks and 229 real stops (plus additional stops and aids). Via electric action it controls 17,974 pipes in 5 separated organs. |

| A curiosity in the world of consoles, the organ of the

Convention Hall, Atlantic City, USA. This is very close to the limits of what can be constructed and played. As to

the number of pipes and volume it is the world's largest organ (as to ranks / pipe rows it is a close second to the

Wanamaker organ, though). The console on the right is without any doubt the world's largest: it contains 7 manuals, the

lowest ones have been enlarged by several octaves (the top ones had to be built in almost vertically in order for the organist to have a fair chance to even reach them), more than 1,000

stop switches on the sides (314 real stops, the rest of them are "extensions" and "transmissions"), 7 swell pedals and hundreds of couplers. Sadly, this organ that was built in the late 1920ies has suffered a lot from decay so that it is by now almost unplayable. The simple maintenance of this 33,000 pipe monstrosity with all its incredible complexity would cost a fortune, let alone a restoration. Still there are plans to do just that – time will tell if that money can be made available from somewhere. But even if this organ should be completely playable some day, especially in the plenum or tutti it is miles away from a real "melodious notion". But it would easily be able to repeat its world record in volume that has already been entered into the Guinness Book of World Records. |

|

| The link between the key and the pipe (key action)

The keys of the manuals and the pedals are linked with the pipes / ranks via the key action. The first organs had simple mechanical (tracker) action in which the pressing of the key was transformed into a pushing motion opening a valve in the chest so that the air could stream into the pipe and make it resound. Self-alignment was first produced by a horn chip, later on by a metal spring (see diagram). |

| You might get a slight notion of what this means by looking at the pictures of part of the traction

compartment leading from the console towards one of the two large 32’ pipe towers of the Weingarten organ system. Basically

this is what it looks like behind the console of any organ with mechanical action (just maybe not as complicated). |

||

|

|

|

| In the 19th century pneumatic action was developed (tube pneumatics). This means that pressure on a key initiates a pneumatic system (compressed air mechanism) connected with the tone valve below the pipe via tubes or hoses opening and closing it pneumatically (similar to a brake servo in a car). The advantage of the pneumatic system was that the organ could be played more easily, even if there was a long distance between the manual and the pipes. Also, key pressure no longer depended on the amount of stops and couplers pulled. |

| Finally, it meant more flexibility in planning an organ, as basically every single pipe could now be placed

anywhere and no longer had to be arranged in rows. On the other hand, pneumatic action had some serious disadvantages: it was quite loud (the typical "pffft") and not very durable,

i.e. it needed frequent repairs. Also, the organist - as opposed to mechanical action - missed the "feeling", the direct connection of key to sound. In the early 20th century electric action was developed. Pressure on the key generates an electric impulse that is transmitted by wire to an electro magnet that can open and close the valve of the appertaining pipe. This kind of action offers the same constructional advantages as pneumatic action, but is easier to build and maintain and less liable to break down. It is the action chosen wherever mechanic action cannot or should not be built in - still it has the same disadvantage of the player not having direct contact with the tone and lacking the "feeling". Some 20 years ago MIDI and computer technology entered the field. A console equipped with MIDI can not only be connected to other MIDI-compatible instruments or computers and control them or be controlled by them. It also means that the organist is able to play a piece and then save it. The system will save exactly the keys the organist struck and repeat the whole sequence on demand. This opens up entirely new opportunities, be it that the organist can listen to his own play "from a distance" or single-handedly play four-handed pieces by first playing the first two voices and saving them by sequencer and then, in concert, add the remaining voices live to the voices recorded by the sequencer. Still, regardless of the type of action employed in a pipe organ the sound itself is still produced solely mechanically. But there are more and more organs that in addition to pipe ranks have digital voices as well. Many purists (myself included) are sceptical of this development, because if you listen closely even the most fantastic digital stop just does not exactly sound like "the real thing". On the other hand a pipe organ, due to the enormous amount of material (pewter, seasoned woods, etc.) and work involved (almost every single part has to be handcrafted), is a very expensive instrument and there are fewer and fewer churches that would be able to afford it, so I'm afraid there is no stopping it... |

| Stop action The transmission from the keys of the manuals and pedalboard to the pipes is just one aspect of action, the other one is the turning on and off of the different ranks (rows of pipes, types of timbre). The whole arrangement is a two-dimensional matrix: in one direction you have the different pipes (tones) and their key action , in the other direction you have the rows rows of pipes (ranks) and the stop action. |

|

The diagram on the right shows a slider chest with mechanical (tracker) key and stop action. The "sliders" open a large valve connecting the wind channel with the whole row of pipes (rank). The wind, though, can only stream into the pipes if the tone valves below the pipes are opened as well, which is achieved by pressing the keys on the keyboard connected to the tone valves. Now if the organist pulls several stops (voices), as many valves leading to the wind chest of the appertaining pipe rows will be opened. For example, when he plays a chord on the keyboard all the connected pipes of every stop will speak. Not only in key action have pneumatic and electric action systems been developed beside mechanical action, this has happened with stop action as well. Electric stop action has the advantage of being able to save and recall different registrations (which actually means combinations of timbre) by just pressing a button, whereas with mechanical action you would have to open and close several stops (voices) if you wanted to change registration. This is what makes many romantic and modern pieces very hard to play as they tend to call for frequent changes of timbre (unless the organist asks someone, the registrant, to be precise, to lend a helping hand). In contrast to key action where direct contact between key and tone is very much desirable, in stop action it does not really matter if the valves are worked mechanically or electrically as they lead to whole sets of pipes and are opened or closed for a longer period of time. Therefore most modern organs have a combination of mechanical key action and electric stop action which makes it possible to pre-set and quickly recall registrations. Basically, there are two ways to pre-set registrations: free combinations and (via setter) programmable combinations. In free combinations any stop is available several times, which means that you can change stops in the 1st, 2nd, 3rd, etc. level just as well during play as the main stops. |

|

| Such consoles usually look gigantic with all those "buttons and switches" (an organ with 100 stops and

four free combinations will have 500 knobs) - still they don't offer enough flexibility in registration as more than four free combinations with all those switches just can't be sensibly

integrated into one console. This is why nowadays programmable combinations are more in use - a system in which using the main stop actions you can select a combination and then save

it in an electronic memory (or floppy, etc.) This way you can pre-set thousands of combinations on different levels and recall them by just pushing a button. MIDI compatible consoles

can even let a computer control the registration as well as record store and playback all actions of the organist. |

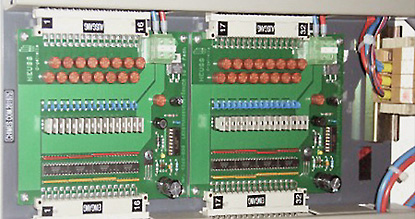

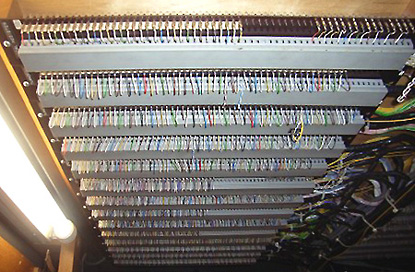

||

On the right and below you can see some details of the electronic control of 4,000 programmable

combinations with sequencer of the great organ at Paderborn Cathedral. It contains 3 separate organs, each one playable from its own

console as well as together from a central (general) console. |

|

|

| ||

| Special aids for playing Depending on their size, organs also offer some so-called aids for playing. These would be crescendo pedal , couplers and swellers. A crescendo pedal (also called "stop sweller") is a revolving foot roll that can add or remove stops in a pre-set order when it is rolled forwards or backwards. This is extremely convenient in playing romantic organ pieces. Couplers can mechanically, pneumatically or electrically combine several manuals, which means that by pressing keys on one manual the keys on the connected manual will be pressed automatically as well, and so their pipes will speak, too. In organs with mechanic action only this is exactly what happens (meaning that the organist has to press the key twice as hard), in organs with electric couplers only the tones will be played without the keys of the coupled manual moving. So the organist just about doesn't notice the coupler. |

|

With electric couplers you can even play the manual that has been connected at a specific range, for example one octave above or below. This kind of coupler is called a super-octave coupler if shifting to the higher pitch, or a sub-octave coupler if shifting to the lower one. Many of these couplers even connect keys on the same manual. In rare cases there is a fifth coupler as well that connects keys a fifth apart. If the organ has "extended" super- or sub-octave couplers there should to be an additional twelve pipes at the upper or lower end of the keyboard (for the last octave) to answer to the coupler. But in many cases they are not - which means that the uppermost or lowest octave on the keyboard cannot be connected by the coupler. One aid that almost every organ offers today is the swell. This is a separate division where the pipes stand in a box with wooden slats arranged like venetian blinds. A special pedal, the swell shoe, controls the opening and closing of these slats so that the organist has a very close control over its volume. To hear the swell effect just click on the sound sample symbol:  The picture on the right shows the lower part of the console of the great organ at the Auen Church (Berlin, Germany). |

|

| The wind supply in an organ | |

|

The air needed for the pipes to speak (usually called the "wind" by organ builders) used to be produced by people treading huge bellows in a side chamber of the organ (see the picture to the left). This way the wind was forced into the reservoirs of the organ. Today a blower worked by a huge electric motor has taken over this job, but the principle remains the same. In order for the sound not to waver, the air must be under constant pressure. As, on the other hand, the amount of wind needed constantly changes depending on the amount of stops pulled and keys played the organ has huge air reservoirs and compensation mechanisms (so-called concussion bellows under the chests) that ensure constant air pressure. With this system it is even possible to produce different wind pressures for the different divisions, subdivisions or even single ranks. Higher air pressure will yield a louder and fuller tone that is less rich in overtones (in the same pipe) than a lower pressure, so by changing the air pressure you can influence the way certain subdivisions sound. Usually air pressures are about 60 - 100 mm WC (water column in a so-called wind scales) which amounts about 2.4 - 4". High pressure stops can be played with air pressures of up to 2,500 mm (approx. 100") - but they sound rather more like a ship's horn or a siren than like an organ stop... In addition to the above mentioned sweller there is another aid to have the organ sound less static, the tremulant (tremolo). The tremulant can periodically open and close the wind channel at a certain small spot and create swayings of air pressure that will cause the sound to "tremulate". In the sound sample on the right you can hear the "Vox Humana" with tremulant:  A final remark: If you think you still haven't got enough information about organs try Wikipedia, the free online encyclopaedia. |

Please note that the diagrams on this page are scans taken from the book "Die Orgel" by Friedrich Jacob (Schott Verlag), textual comments on the diagrams are mine. The diagrams can be enlarged by clicking on them. The sound samples of the organ stops are taken from the CD "Das Geheimnis Orgel", played by Paul Wißkirchen at the Altenberg Cathedral Organ with kind permission of TMK-Group Media Production & Marketing (Cologne). |